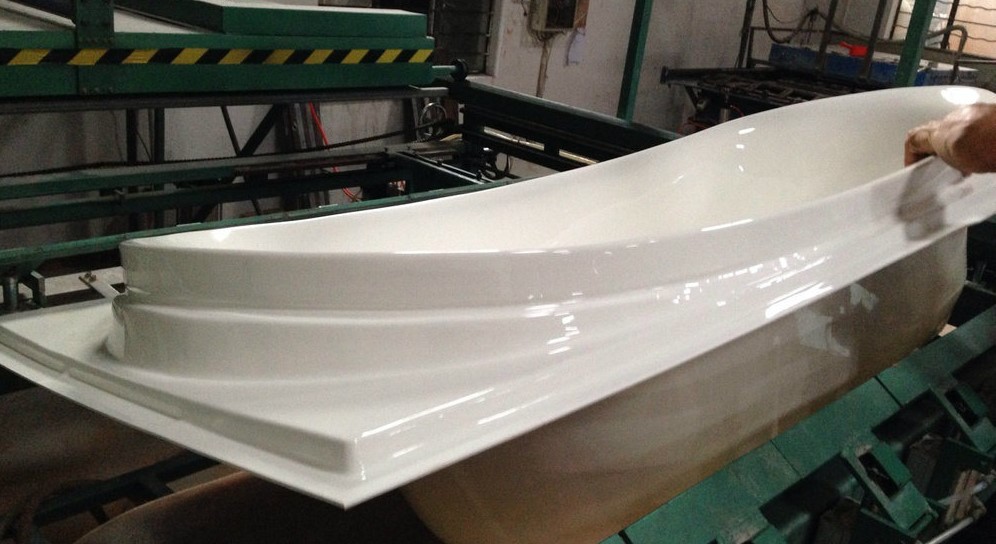

MOLDS FOR THERMOFORMING MACHINE

After several tests, MCPROD succeeded in manufacturing molds in composite materials for vacuum thermoforming

the key point is to have a surface in contact with the heated plastic that can withstand around 200°C

the development of aluminum molds for the plastic industries seems constrained since the costs and the nature of the manufacturing which requires several techniques is not obvious

composites have their advantages in terms of cost, repair and ease of duplication

What is Vacuum Forming & Thermoforming ?

Vacuum forming is a type of thermoforming: heat used to form a design. Thermoforming processes include vacuum forming, pressure forming, and twin sheet forming. Each of these processes uses a mold or molds to shape heated sheets of plastic into the desired form.

Types of Plastic for Vacuum Forming :

- ABS – acrylonitrile butadiene styrene)

- Acrylic – PMMA – Poly(methyl methacrylate)

- HDPE – high density polyethylene

- HIPS – high impact polystyrene

- PC – polycarbonate

- PET – polyethylene terephthalate

- PETG – polyethylene terephthalate glycol

- PP – polypropylene

- PS – polystyrene

- PVC – polyvinyl chloride